Breguet’s Art Of Guilloché Engraving: A Masterclass

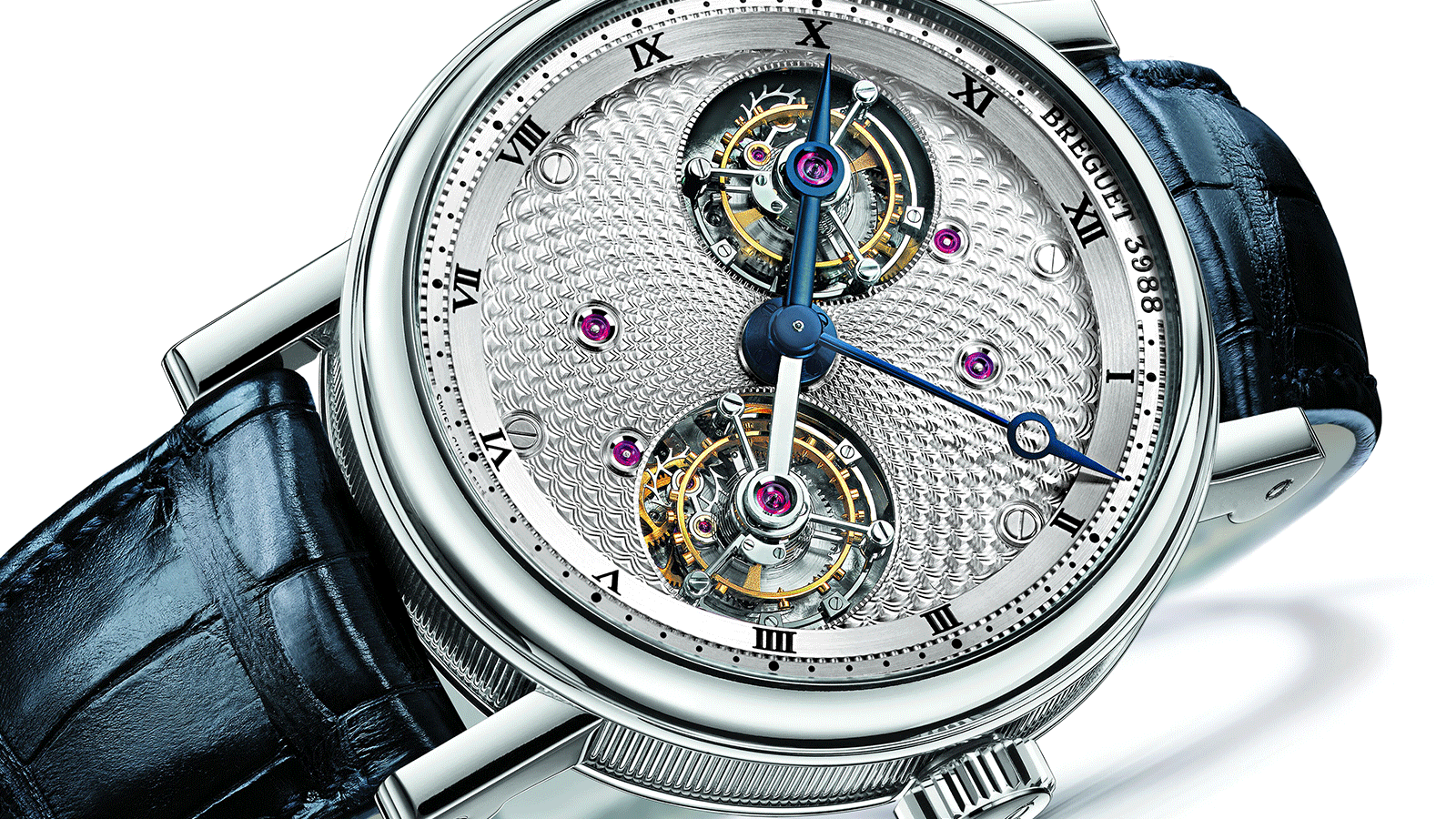

Montres Breguet, a name synonymous with horological excellence, has long been revered for its unparalleled mastery of guilloché — a centuries-old engraving technique that transforms watch dials into intricate works of art. Pioneered by the legendary watchmaker Abraham-Louis Breguet in the late 18th century, the use of the rose engine lathe to create precise, repetitive patterns has become a hallmark of the brand. In 1999, when Breguet became a part of the Swatch Group, Mr. Nicolas G. Hayek invested heavily in the craft of guilloché – training artisans, and today Breguet has the biggest guilloché workshop in the industry. Breguet’s innovative integration of guilloché not only enhances the aesthetic appeal of its timepieces but also improves functionality by reducing glare and increasing legibility. Today, Breguet continues to blend traditional craftsmanship with modern technology, preserving the timeless beauty and meticulous artistry that define its watches. Read on to learn more about the history of this fascinating technique and discover why Breguet continues to employ it liberally in its expert watchmaking today.

What is guilloché’ engraving?

For those not familiar with the term ‘guilloché’, it’s worth spending a few moments exploring what it actually entails. In the simplest terms, guilloché is an intricate decorative technique used primarily in watchmaking (although it can be found in other fine crafts also), where a repetitive, engraved pattern is created on a metal surface. In essence, a series of very fine, precise lines form a pattern, such as tiny waves, spirals, or grids, that cover a surface, giving it a textured and reflective quality. It sounds simple enough but, it is a time-consuming and highly demanding process that takes years to master.

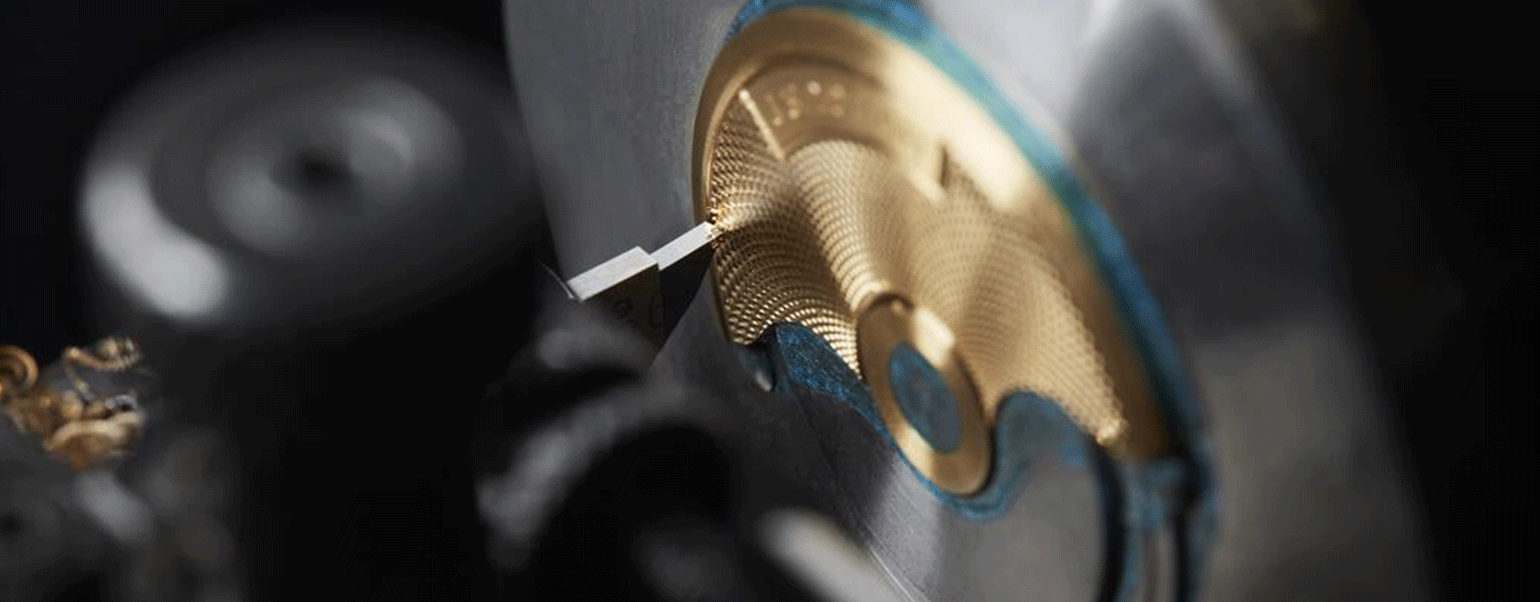

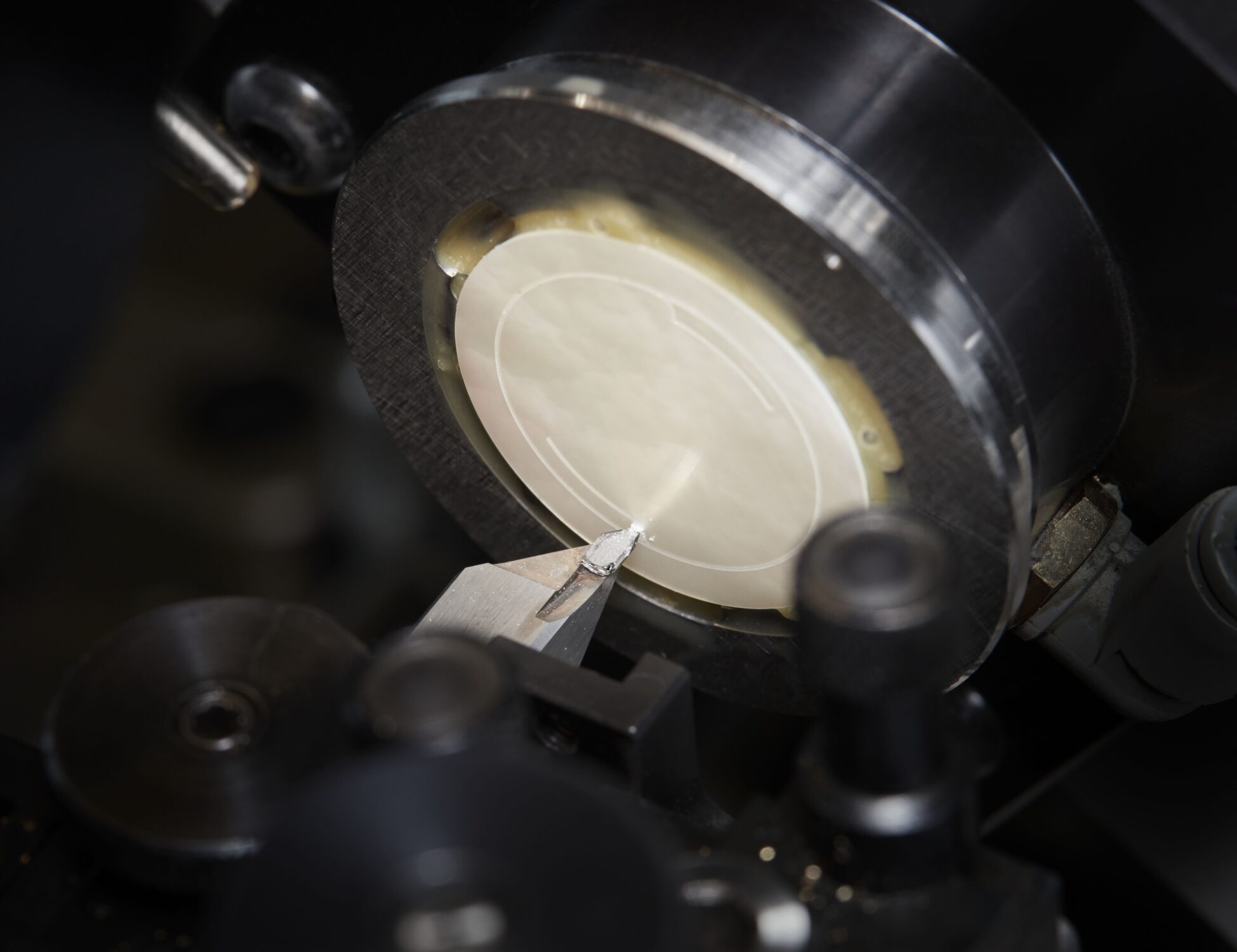

To create those very fine, precise lines a skilled artisan uses a special machine called a rose engine. This machine has various settings and templates (called rosettes) that guide a cutting tool over the metal, carving out the design. The patterns are not just for decoration; they also have practical benefits, like reducing glare on a watch dial, making it easier to read. It’s a slow process though and one which requires immense patience. Each pass of the cutting tool removes only a tiny amount of material, meaning that creating a single pattern can take several hours or even days. Likewise, consistency in the pattern is crucial. Any deviation or error can ruin the symmetry and overall appearance of the design, and in the case of Breguet’s exacting standards, could even necessitate discarding the work in progress and beginning again. A high level of attention to detail is a non-negotiable requirement for mastery of this craft, as well as a healthy dose of determination.

In sum, think of guilloche engraving as a way to add both beauty and function to an object, turning a plain surface into something visually stunning and unique. It turns a piece of metal, such as a dial blank, into a canvas and demands creative flair, an expert eye, and a steady, patient hand to painstakingly engrave fine, precise lines to create a piece of art that also serves a practical purpose.

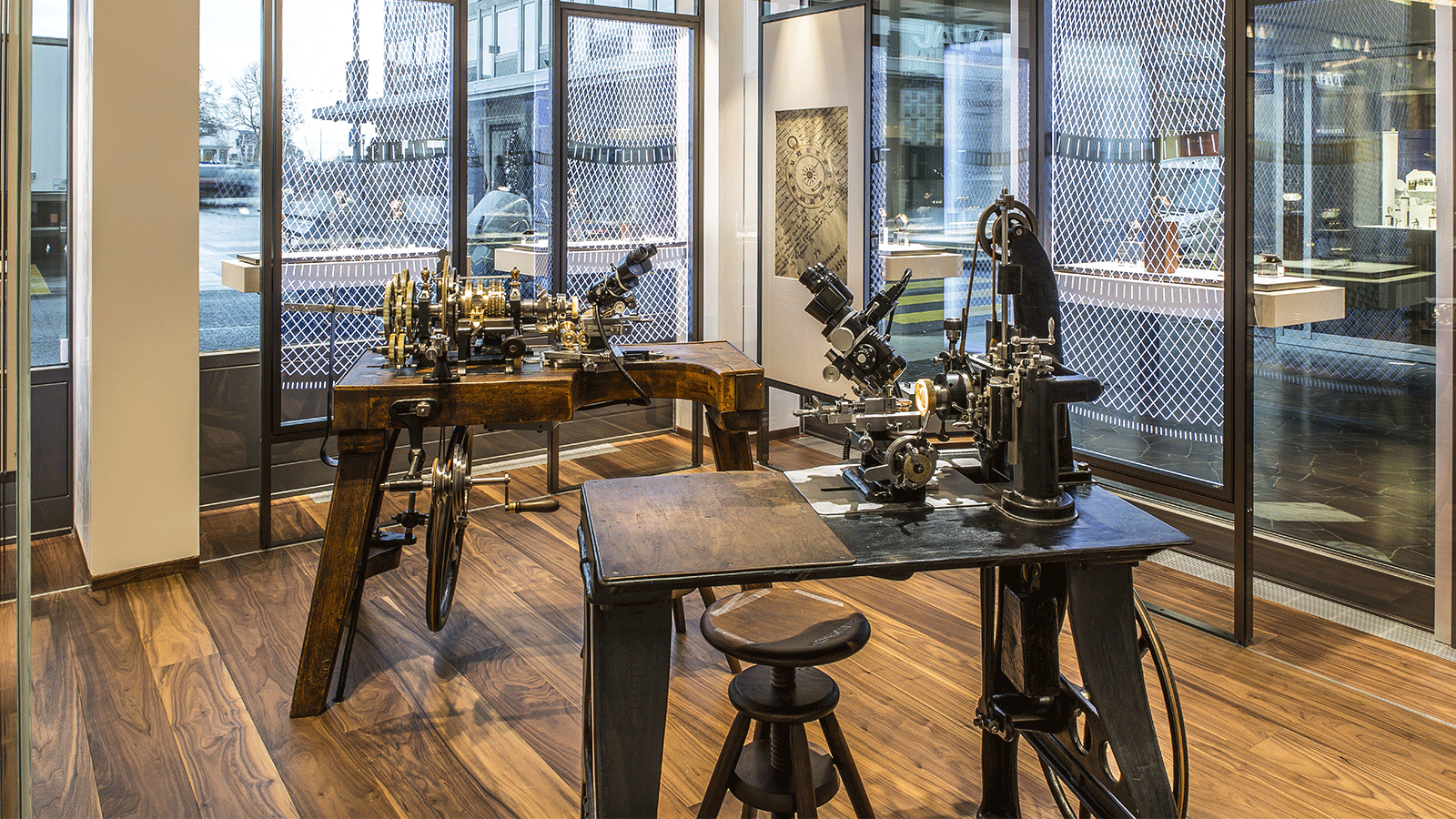

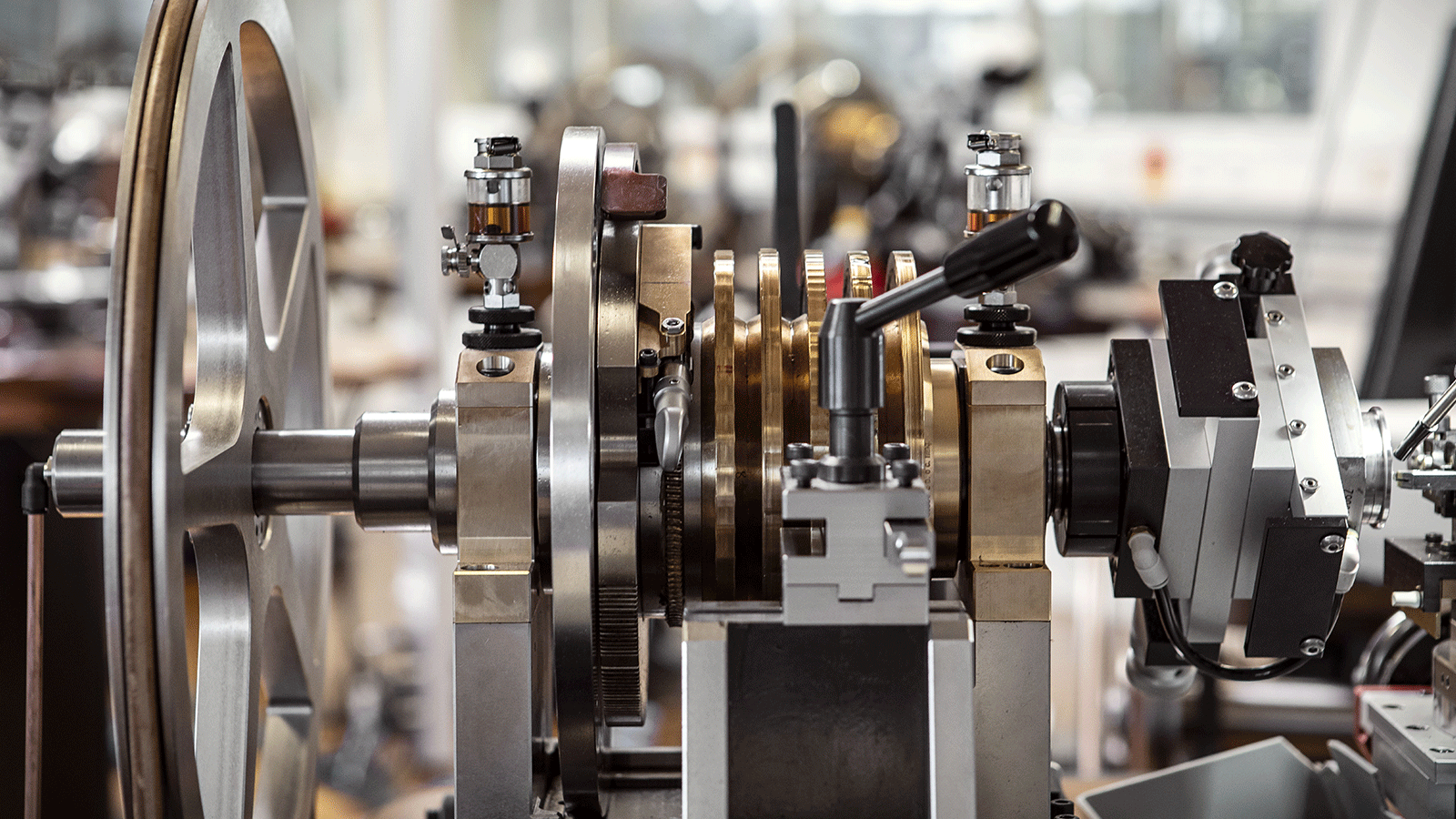

The Rose Engine Lathe

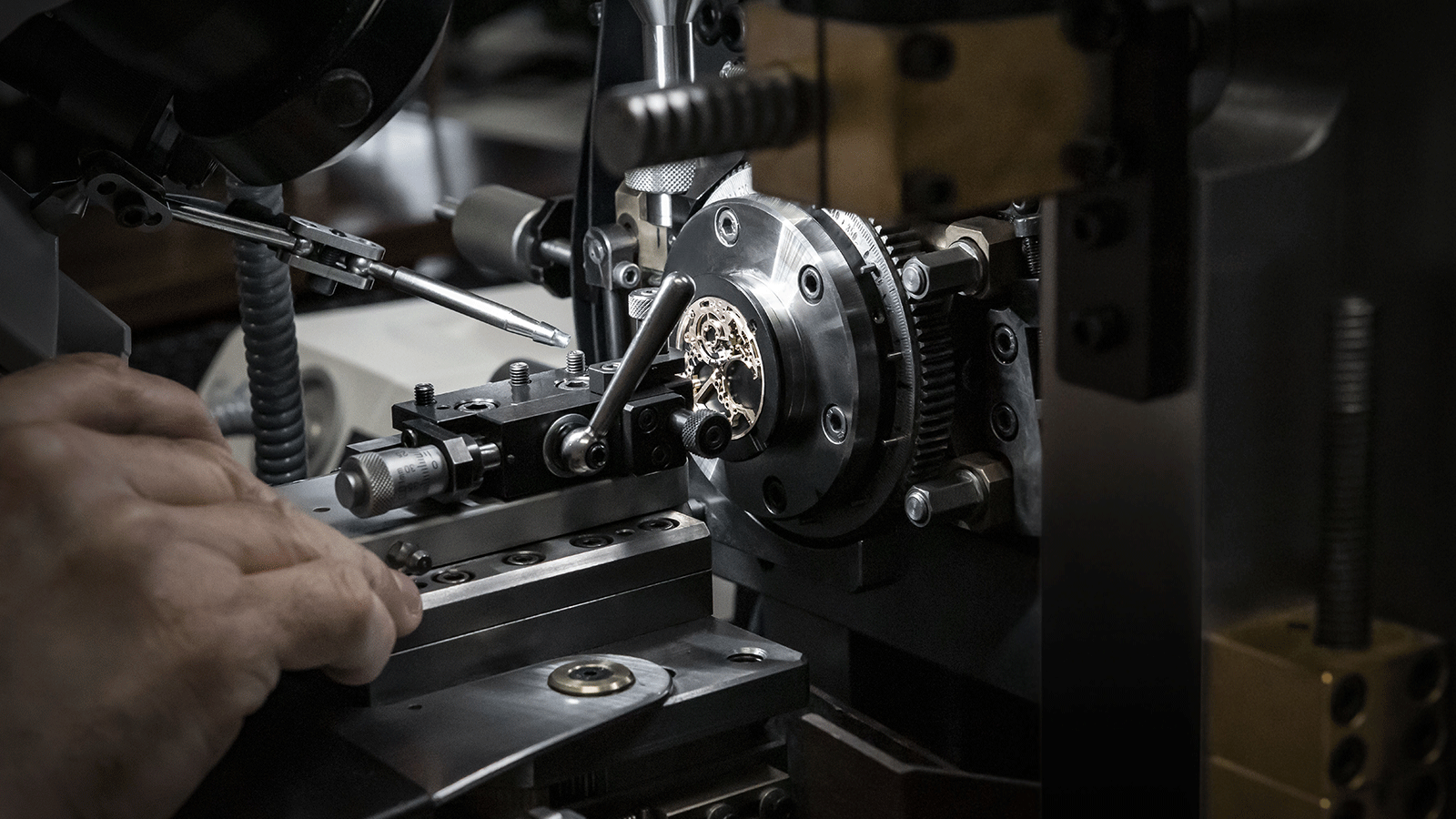

An ingenious invention, the rose engine consists of a spindle that holds the workpiece and a series of interchangeable rosette cams, each with a different pattern. The spindle is mounted on a rocking frame, allowing it to move back and forth in response to the contours of the cam. By changing the cam, the artisan can switch between different patterns, such as waves, spirals, or floral motifs. The cutting tool is mounted on a carriage that moves horizontally. This carriage can be adjusted to control the depth and position of the cut. As the spindle rotates and rocks back and forth, the cutting tool is guided over the surface of the workpiece, engraving the pattern dictated by the cam.

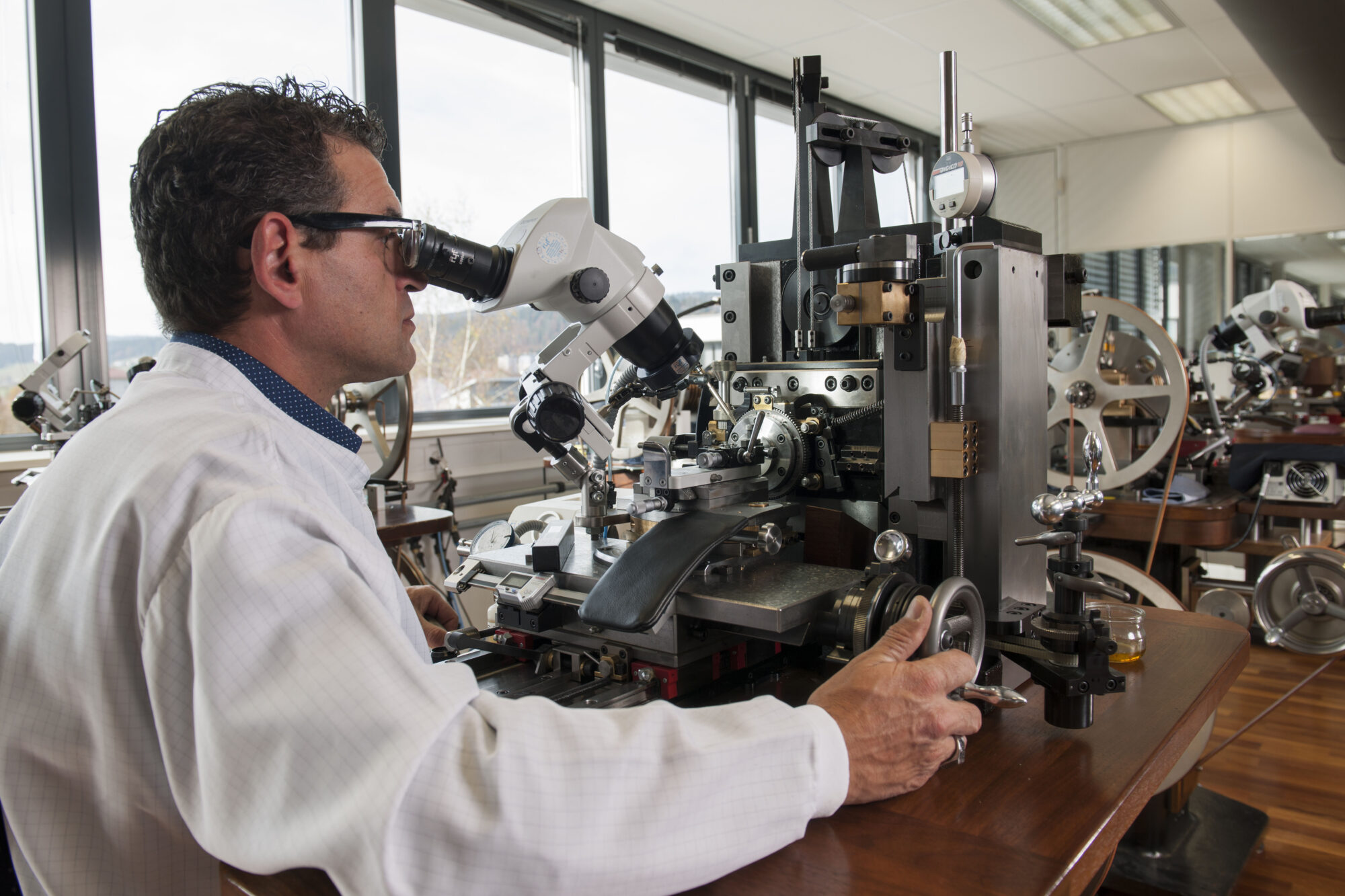

The process is highly manual, requiring the artisan to constantly adjust and control the cutting tool and the movement of the spindle. The speed of rotation, the pressure applied, and the synchronization between the rocking motion and the cutting tool’s advancement all need to be meticulously controlled. Operating a rose engine for guilloché is a blend of art and science, requiring technical skill, artistic vision, and years of dedicated practice. The intricate patterns produced by this technique are a testament to the artisan’s mastery and the timeless beauty of hand-crafted horology.

The Abraham Louis Breguet Influence

Breguet’s founder and namesake Abraham Louis Breguet (1747 – 1823) didn’t invent the rose engine lathe – this achievement is commonly attributed to the Swiss-born mechanic and watchmaker, Jacob Auch, around the 1780s – however, he did play a key role in popularising its use in watchmaking. In fact, Breguet was among the first watchmakers to adopt the use of the rose lathe for creating guilloché patterns on watch dials, producing beautiful patterns that added depth, texture, and elegance to his watch dials. These patterns not only made the dials more attractive but also helped to diffuse light, reducing glare and improving legibility.

As with every aspect of his craft, Breguet set high standards for the use of guilloché in watchmaking. His use of the rose lathe was marked by exceptional precision and symmetry, with the techniques he developed influencing not only his contemporaries but also future generations of watchmakers. Many of the designs he developed are still used by Breguet today, as well as by other luxury watch brands that seek to emulate his level of craftsmanship.

Historical examples include the Breguet No. 5, which he created in 1794. It features a guilloché dial that showcases Breguet’s mastery of the rose lathe technique. The intricate patterns add both beauty and functionality to the timepiece. Likewise, one of A-L Breguet’s most famous creations, the Marie-Antoinette watch, features a richly decorated dial with guilloché patterns. This watch is a testament to Breguet’s skill and artistic vision.

Montres Breguet and the Art of Guilloché

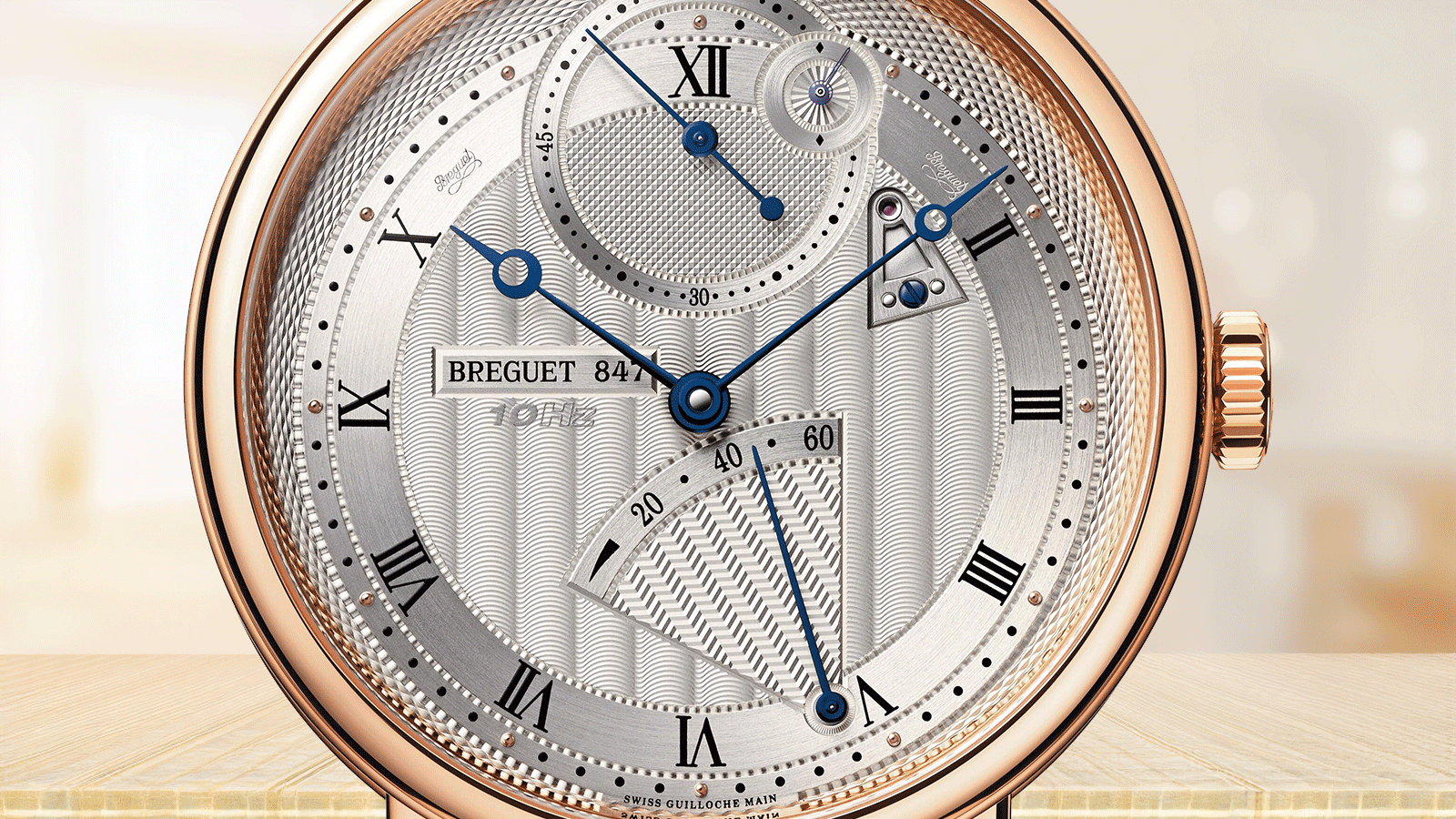

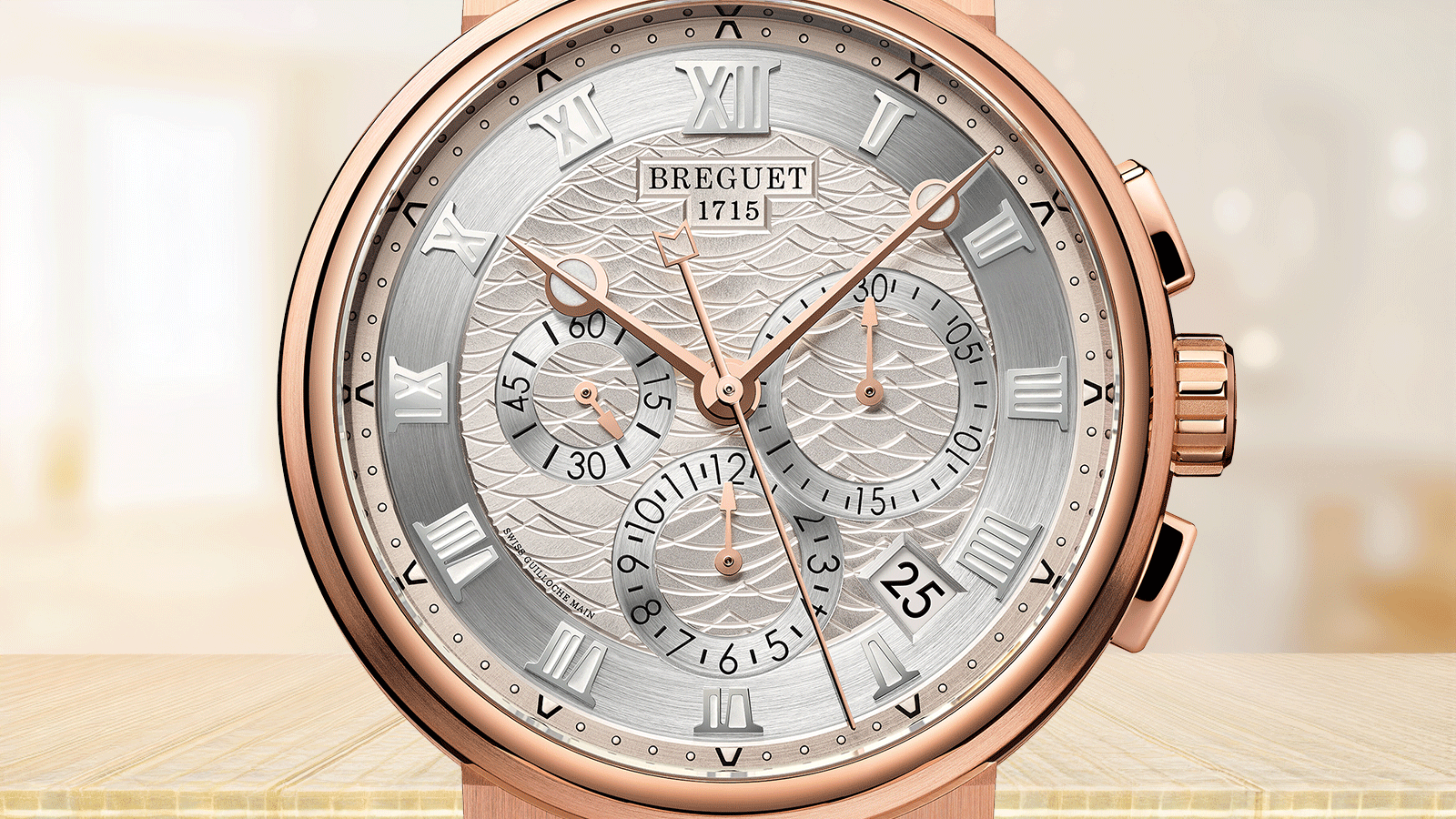

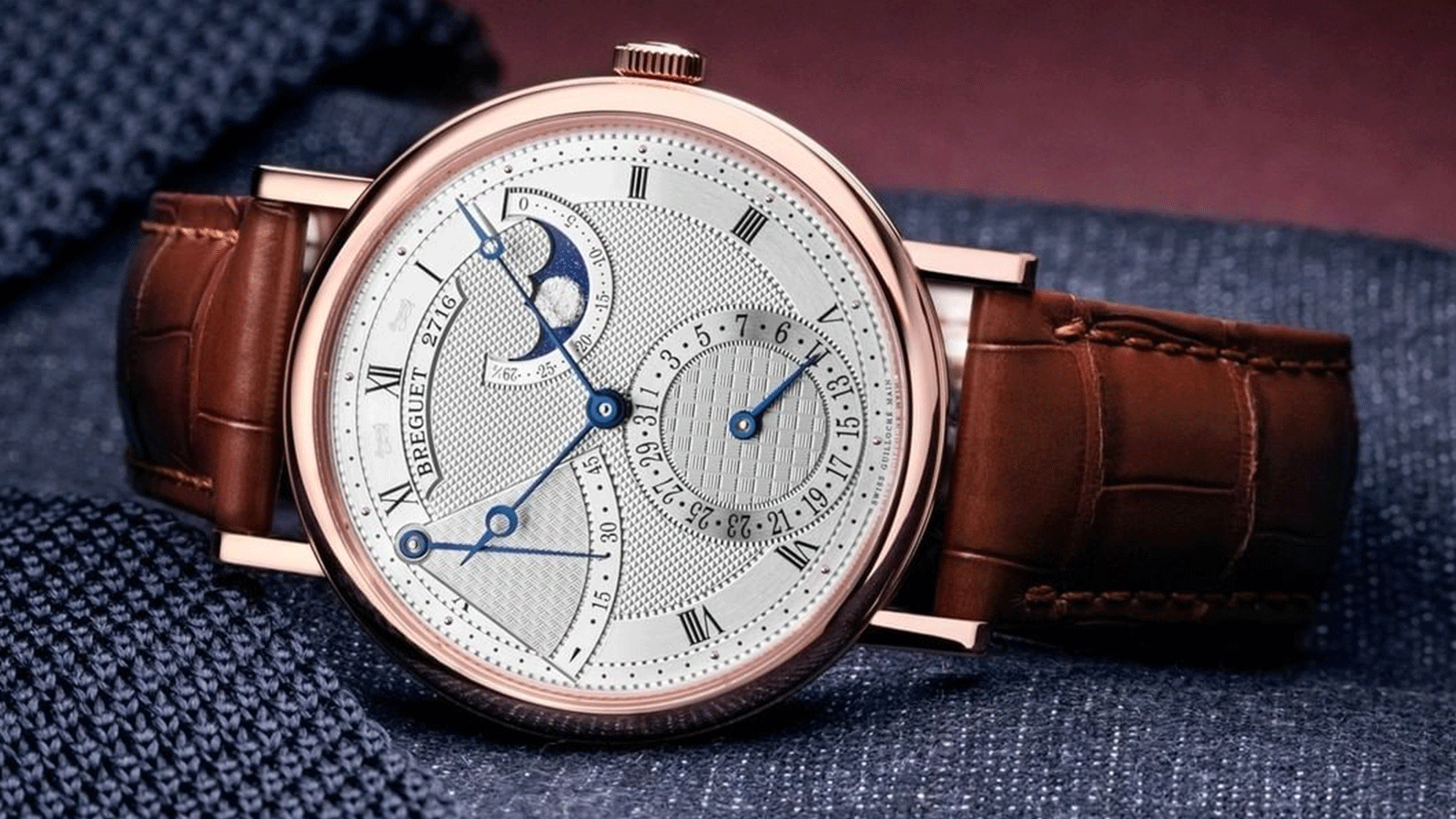

In contemporary Breguet watches, guilloché remains a prominent feature, symbolizing the brand’s commitment to traditional craftsmanship and elegance. The patterns are often applied to dials, rotors, and casebacks, enhancing both the visual appeal and the heritage value of the timepieces. Breguet has also pioneered techniques to create multi-layered guilloché patterns, adding depth and complexity to the designs. This involves layering different patterns on top of each other to produce a three-dimensional effect. This technique requires a high level of precision and coordination, blending traditional craftsmanship with modern innovation.

Drawing heavily on the influence and handiwork of its namesake, Breguet employs a variety of guilloché patterns in its modern-day creations, each serving different aesthetic and functional purposes. Some of the more recognisable traditional patterns include:

• Clous de Paris (sometimes referred to as hobnail) – characterized by small, pyramid-shaped studs arranged in a grid pattern, it is used to add texture and depth, typically to a watch dial but also sometimes to the watch case itself.

• Sunburst or Radiating Lines – usually found on sub-dials or as a background to other dial elements, this technique calls for lines emanating from a central point, giving a sense of motion and vibrancy. A-L Breguet often used this style of guilloché to distinguish subdials from the main dial, a technique Montres Breguet continues to adopt to great effect today.

• Waves or Wavy Lines – In 1815, A-L Breguet obtained an official appointment as chronometer-maker to the French Navy, forever cementing the brand’s connection to the seas. This technique produces fluid, undulating patterns that mimic the appearance of waves and is prominently found on timepieces in Breguet’s contemporary Marine collection.

• Basket Weave – As the name suggests, this decorative technique is comprised of intersecting lines that create a woven appearance. It is extremely complex to produce and truly showcases the skill of the artisan at work.

Breguet has also been known to explore contemporary aesthetics, incorporating modern art and design elements into its guilloche engraving. Innovative designs include abstract patterns, modern geometric shapes, and even inspirations from nature and architecture.

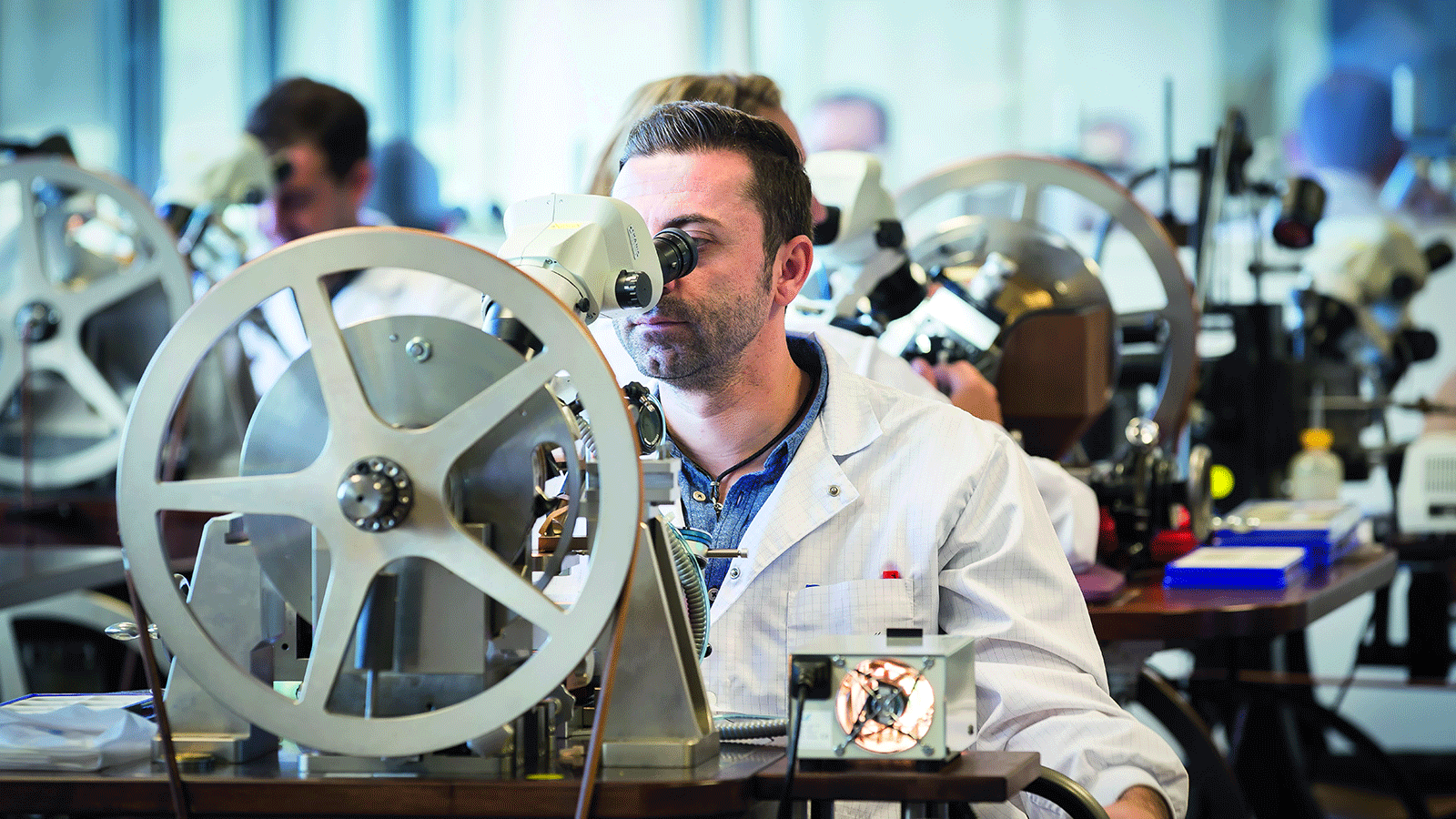

No matter what pattern is used, Breguet has a rigorous quality control process to ensure that every guilloché design meets the brand’s exacting standards. The use of microscopes and other precision instruments during the engraving process ensures that even the smallest details are perfectly executed and each complete piece is meticulously inspected for uniformity, depth, and overall aesthetic quality.

Likewise, Breguet regularly invests in high-precision tools and machinery as well as in training new generations of artisans, ensuring that the knowledge and skills required for guilloché are passed down and preserved. This includes both traditional techniques and modern innovations. These training programs are essential for maintaining the high standards of craftsmanship that Breguet is known for.

Breguet’s modern innovations in guilloche engraving reflect a harmonious blend of tradition and technology. By integrating advanced materials, tools, and techniques, Breguet continues to push the boundaries of what is possible in guilloché, while preserving the timeless beauty and craftsmanship that define the brand.

Discover Breguet Guilloché at Watches Of Switzerland Today

Watches of Switzerland is privileged to partner with Montres Breguet in Australia, offering a deep selection of models at our Sydney, Melbourne, and Perth boutiques. Book a private viewing with our knowledgeable consultants to truly appreciate the intricate beauty of these designs. With guilloché decorations showcased in all Montres Breguet collections, you’ll discover the ideal timepiece for yourself or a cherished companion.

Rolex

Rolex A. Lange & Söhne

A. Lange & Söhne Blancpain

Blancpain Breguet

Breguet Breitling

Breitling Cartier

Cartier Hublot

Hublot Vacheron Constantin

Vacheron Constantin IWC Schaffhausen

IWC Schaffhausen Jaeger-LeCoultre

Jaeger-LeCoultre OMEGA

OMEGA Panerai

Panerai Roger Dubuis

Roger Dubuis TAG Heuer

TAG Heuer Tudor

Tudor FOPE

FOPE Agresti

Agresti L’Épée 1839

L’Épée 1839